Case Studies

Ermico Enterprises

US HydroTech custom designed this ClearTreat system for Ermico Enterprises, a skateboard manufacturer in San Francisco. The size, capacity and operating characteristics of each system was tailored to the company’s specific needs.

ClearTreat Reactant provides superior separation and flocculation, in a simple, affordable process. ClearTreat is a mixture of Sodium Bentonite clay and select polymers. This one-step dry reactant is an excellent choice for removing oils, greases, and metals found in most wastewater streams. Designed for low-flow, high-loading waste streams, ClearTreat allows the system to work with little to no dilution.

How ClearTreat Works

When ClearTreat enters the waste stream, it releases a dry acid which causes the oil to coalesce and separate from the wastewater. The polymer attracts and entangles oil particles and draws the clay into the entangled mass.

Next, a dry base is released, causing the metallic hydroxides to precipitate. The polymer, with its entangled containments, is attracted to the ClearTreat. The oils and metals bond into the interior of the ClearTreat platelets, locking them in.

The ClearTreat then starts to gather in larger clumps, creating a floc. The resulting mass is a mixture of microencapsulated containments and waste solids held together by electrostatic forces. The containments that were microencapsulated become surrounded by a barrier of clay particles and are not available to external leaching fluids, which are kept from the interior of the clay pocket.

Once the ClearTreat has completed its process, the mixture of ClearTreat and the wastewater is processed through a separation media. The ClearTreat, which is now a flocculent, is separated from the water. The flocculent emerges in the form of sludge which, in most cases, can be managed as a non-hazardous waste. The treated water is now ready for reuse or discharge.

CONTACT US

TALK WITH AN EXPERT

We have a cost-effective and environmentally friendly solution for operations of all shapes and sizes in the United States.

Contact Us – Sidebar

related CASE STUDIES

Recology

Project Type: BIO Enzyme Water Recycle System

Equipment: BIO Enzyme Water Recycle System; Submersible Sump Pump; Bioreaction Tank; Biofilm Generative Media; Aeration System; Pressurized Tank

Learn More

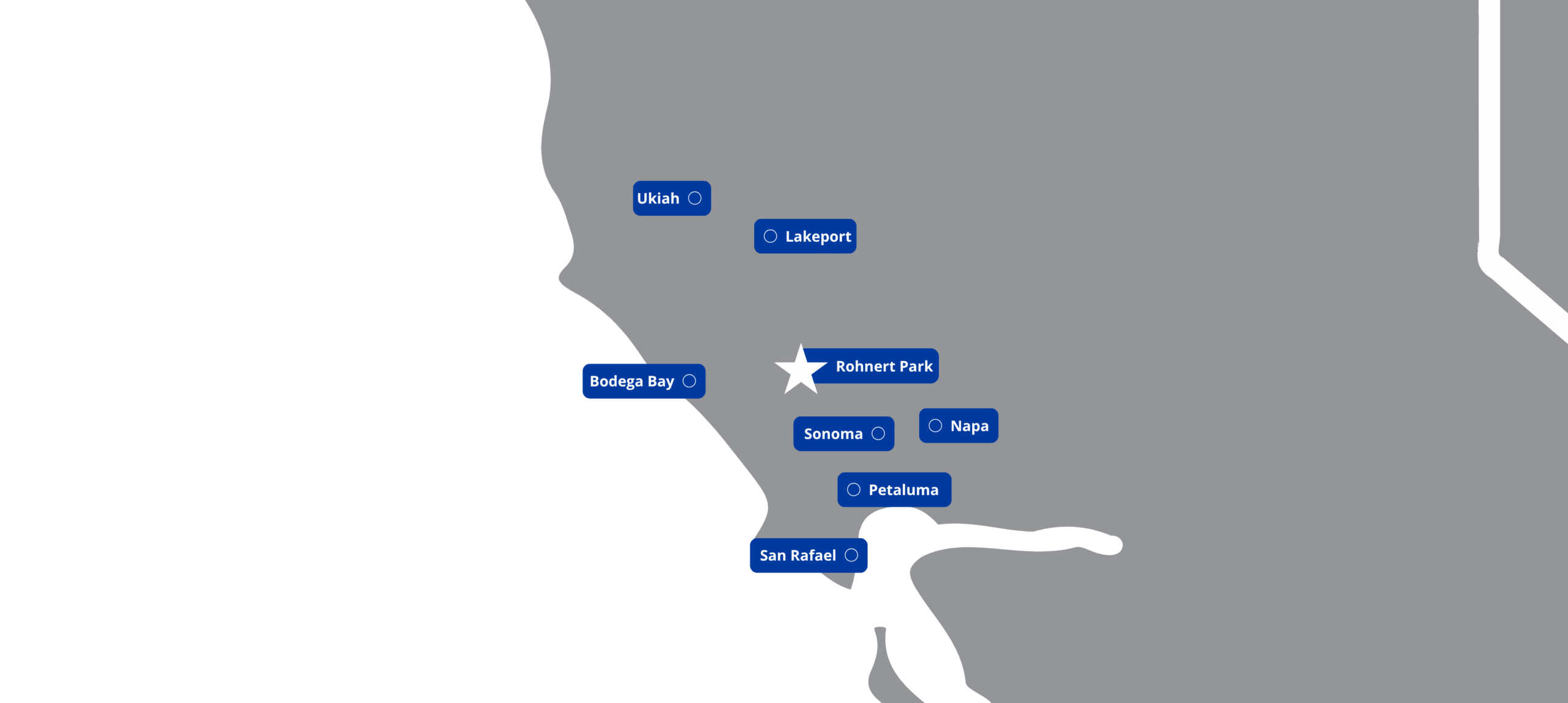

CONVENIENT LOCATIONS

Servicing THE NORTHERN BAY AREA

We provide quality service and repair for your industrial pressure cleaning equipment in the Sonoma County, California area. We offer in-store or on-site (within 40 miles) servicing and preventative maintenance.